8 Hp Briggs And Stratton Operators Manual

Briggs & Stratton 1-F1 190cc/8.75 Gross Torque, 1.6 Quarts Fuel Tank, Ext. Starter Rope, 12 Volt Gear Drive Starter and.5 Amp DC Alternator, ReadyStart, OHV, Tapped 3/8-24, 2 WK & Keyway, 25mm Dia. Crankshaft Engine.

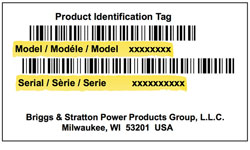

- To obtain the operator's manuals, illustrated parts list or detailed help information for your Vanguard™ engine, you must search by your engine model number.

- Apr 28, 2008 - Thank you for purchasing this quality-built Briggs & Stratton generator. We are pleased. Read entire operator's manual before you attempt.

. For Briggs & Stratton Discount Parts Call 606-678-9623 or 606-561-4983 Please click the “Bookmarks” tab at left to enable the search and navigational features of this document. ® 5 HP Outboard Troubleshooting & Repair Manual www.mymowerparts.com. FORWARD This guide has been written and published by Briggs & Stratton Corporation to aid our dealers' mechanics and company service personnel when servicing the products described herein. It is assumed that these personnel are familiar with the servicing procedures for these products, or like or similar products, manufactured by Briggs &. 5 HP Outboard. Troubleshooting & Repair Manual Table of Contents TABLE OF CONTENTS INTRODUCTION DISASSEMBLY In the Interest of Safety Cooling Shroud Safety Alert Symbols Removal Fuel Recommendations Power Head Gasoline Blower Housing Oil Recommendations Magnetron™ Ignition Lubrication System.

5 HP Outboard. Troubleshooting & Repair Manual Table of Contents TABLE OF CONTENTS Install Flywheel OVERHAUL Install Armature Magnetron Ignition Armature Air Gap Remove Armature Cylinder Head Assembly Inspect Valve Springs Install Cylinder Head Plate and Rocker Arm Studs. 5 HP Outboard. Troubleshooting & Repair Manual Section 1. Introduction Introduction In the Interest of Safety Safety Alert Symbols Fuel Recommendations Gasoline Oil Recommendations Lubrication System Engine Oil Oil Drain Plug, Oil Fill and Dipstick Gear Selector Operation. 5 HP Outboard.

Troubleshooting & Repair Manual Section 1. Introduction DANGER DESIGNED FOR FRESH WATER WARNING CAUTION: Salt water is extremely corrosive Storage batteries give off Fuel and its vapors are extremely to outboard components. Failure or damage related explosive hydrogen gas during flammable and explosive.

5 HP Outboard. Troubleshooting & Repair Manual Section 1.

Introduction INTRODUCTION In the Interest of Safety. DO NOT tamper with links or other parts to increase engine speed.

(This engine uses a non- Safety Alert Symbols adjustable, electronic engine speed limiter.). 5 HP Outboard. Troubleshooting & Repair Manual Section 1.

Introduction Fuel Recommendations SAE 30 Gasoline Use clean, fresh, unleaded gasoline. Leaded gasoline may be used if unleaded is not available. A minimum of 85 octane is Synthetic 5W-30W, 10W-30 recommended. 5 HP Outboard. Troubleshooting & Repair Manual Section 1. Introduction 4. Install drain plug.

Torque to 10 ft. Figure 4 — Gear Selector Operation 5.

Remove dipstick Refill slowly with (Figure 2) 24 oz. (0.75 qt., 0.7 L) of new oil with the proper service classification and viscosity grade. 5 HP Outboard. Troubleshooting & Repair Manual Section 1.

Briggs And Stratton 6.5 Hp Manual

Introduction Reverse Forward When the shifter is moved to the position, the When the shifter is set to the position, the REVERSE FORWARD shift cam ( is pressed down to its lowest. 5 HP Outboard. Troubleshooting & Repair Manual Section 1. Introduction Changing Gear Case Oil 1. Remove oil drain/fill plug and vent plug (Figure 9) Figure 9 — Gear Case Oil 2. Drain the gear lube into an approved container. 5 HP Outboard.

Troubleshooting & Repair Manual Section 1. Introduction. 5 HP Outboard. Troubleshooting & Repair Manual Section 2. Troubleshooting Troubleshooting Troubleshooting Check Lower Unit No Start - Hard Start Vibration Power Loss Noise Cooling Check Ignition Armature Test Tests for No Spark Neutral Switch Test Check Compression.

5 HP Outboard. Troubleshooting & Repair Manual Section 2. Troubleshooting. 5 HP Outboard.

Troubleshooting & Repair Manual Section 2. Troubleshooting TROUBLESHOOTING Troubleshooting No Start - Hard Start 1. Check remote control assembly for proper Most complaints concerning engine operation can be adjustment. Classified as one or a combination of the following: 2. 5 HP Outboard. Troubleshooting & Repair Manual Section 2. Troubleshooting Figure 11 — Ignition Schematic 1.

Safety/Engine Stop Switch Check Ignition 2. BLACK Wire - to Safety/Engine Stop Switch WARNING 3. Connector Be sure there is no fuel or fuel 4. 5 HP Outboard.

Troubleshooting & Repair Manual Section 2. Troubleshooting Armature Test 3. Remove safety/engine stop switch clip (Figure 13) Figure 13 — Safety Stop Switch Clip WARNING Do not remove spark plug when checking ignition. A fire or explosion may occur. 5 HP Outboard.

Troubleshooting & Repair Manual Section 2. Troubleshooting 7. Insert clip to safety/engine stop switch (Figure 13) Figure 16 — Neutral Switch Test and retest the switch for continuity. There should be no continuity. Use steps 6 and 7 to verify a working safety/engine stop switch and wires. 5 HP Outboard. Troubleshooting & Repair Manual Section 2.

Troubleshooting 4. Hold flywheel nut with 15/16' socket and 1/2' breaker Figure 17 — Shift Lever Continuity Test (Figure 18). Figure 18 — Holding The Flywheel CAUTION NOTE: Local laws may require the use of a Injury may occur if the resistor spark plug to suppress ignition signals. 5 HP Outboard. Troubleshooting & Repair Manual Section 2.

Troubleshooting Check Carburetion 8. Slowly open the valve and note the reading on the gauge. Before making a carburetion check, fill the fuel tank with 9. Listen for air leaking from cylinder head gasket, fresh, clean gasoline. 5 HP Outboard.

Troubleshooting & Repair Manual Section 2. Troubleshooting Figure 20 — Steering Tension Adjustment Figure 22 — Propeller Drive Couplings 4. Inspect the exposed end of the propeller shaft for wear or damage. If the threads. 5 HP Outboard. Troubleshooting & Repair Manual Section 2. Troubleshooting.

5 HP Outboard. Troubleshooting & Repair Manual Section 3. Disassembly Disassembly Cooling Shroud Removal: Power Head Blower Housing Magnetron™ Ignition Flywheel Inspect Flywheel Key, Keyway, Flywheel and Crankshaft Carburetor Disassemble Carburetor Carburetor Cleaning Disassembly Cylinder Head Prepare Cylinder Head for Removal. 5 HP Outboard.

Troubleshooting & Repair Manual Section 3. Disassembly.

5 HP Outboard. Troubleshooting & Repair Manual Section 3. Disassembly DISASSEMBLY Cooling Shroud Figure 25 — Temporary Knot NOTE: The cooling shroud must be removed to access the power head, wiring harness and other serviceable components. Remove the top cover. 5 HP Outboard.

Troubleshooting & Repair Manual Section 3. Disassembly Blower Housing 3.

Remove the throttle cable clamp (Figure 27) 1. Remove four screws, two (Figure 29A and B) Figure 27 — Throttle Cable Clamp from front and two from rear of blower housing as shown. 5 HP Outboard. Troubleshooting & Repair Manual Section 3. Disassembly NOTE: Elbow does not need to be (Figure 31) (#19203) Figure 33 — Flywheel Puller removed except to be replaced if damaged.

Figure 31 — Plug Elbow NOTE. 5 HP Outboard.

Troubleshooting & Repair Manual Section 3. Disassembly Inspect Flywheel Key, Keyway, 3.

Remove speed limiter retaining strap. Flywheel and Crankshaft 4. Remove screws, Set aside air horn (Figure 37) and gasket. Disconnect breather tube. Replace the flywheel key. 5 HP Outboard.

Troubleshooting & Repair Manual Section 3. Disassembly Disassemble Carburetor Figure 40 — Remove Welch Plug 1. Remove bowl screw/fixed main jet (Figure 39) with fiber washer Figure 39 — Carburetor Float Components Carburetor Cleaning 1.

Disassemble carburetor. 5 HP Outboard. Troubleshooting & Repair Manual Section 3. Disassembly Cylinder Head Disassemble Cylinder Head 1. Loosen rocker arm adjusting nut set screws Prepare Cylinder Head for Removal.

Remove rocker arm adjusting nuts (Figure 43) Before cylinder head can be removed, muffler guard and and rocker arms muffler must be removed. 5 HP Outboard. Troubleshooting & Repair Manual Section 3. Disassembly 7. Slowly relieve tension on spring and retainer. Figure 46 — Engine Timing Marks 8.

Remove retainer, spring, valve and valve stem seal (intake only). Discard valve stem seal. 5 HP Outboard. Troubleshooting & Repair Manual Section 3.

Disassembly Piston and Connecting Rod Figure 50 — Removing Propeller Shaft Carrier 1. Remove any carbon or ridge at top of cylinder bore to prevent ring breakage. Tool (#19557) 2. 5 HP Outboard. Troubleshooting & Repair Manual Section 3. Disassembly Figure 52 — Remove Gear Case 7. Pull the drive shaft out (arrow) from (Figure 54) the pinion gear.

Remove the pinion gear and the forward gear/bearing assembly from the gear case. 5 HP Outboard.

Troubleshooting & Repair Manual Section 3. Disassembly 3. With the shaft properly installed to the tool, remove 8. Remove two stainless steel screws (Figure 55) and discard the roll pin from the (Figure 56) stud. 5 HP Outboard.

Troubleshooting & Repair Manual Section 3. Disassembly Midsection Figure 58 — Remove Tilt Bracket Disassembly 1. Remove the nut from the opposite side of the transom bracket bolt. Remove the (Figure 57) transom brackets.

5 HP Outboard. Troubleshooting & Repair Manual Section 3. Disassembly Throttle Cable Rewind Starter Replacement NOTE: Rewind starters used on these model series engines are riveted to the blower housing. Pull the rubber grip from the tiller. 5 HP Outboard.

Troubleshooting & Repair Manual Section 3. Disassembly Figure 61 — Rewind Starter Pulley Figure 63 — Starter Pulley Spring 3. Inspect spring for broken ends, kinks and burrs. Replace assembly if any of the above conditions exist. 5 HP Outboard. Troubleshooting & Repair Manual Section 3. Disassembly.

5 HP Outboard. Troubleshooting & Repair Manual Section 4. Overhaul Overhaul Magnetron Ignition Remove Armature Inspect Valve Springs Inspect Valve Guides Finish Ream Valve Guides Reface Valves and Seats Remove Piston Rings Check Piston Ring Groove Wear Check Piston Ring End Gap.

5 HP Outboard. Troubleshooting & Repair Manual Section 4. Overhaul. 5 HP Outboard. Troubleshooting & Repair Manual Section 4. Overhaul OVERHAUL Magnetron Ignition 1.

Thoroughly clean lapping compound from valve seat and valve face. Remove Armature 2. Valve seat width should be as shown (Figure 65B) The best means of testing Magnetron™ armatures is on the 3. 5 HP Outboard. Troubleshooting & Repair Manual Section 4. Overhaul 1. Grasp one end of the steel rail and wind the rail from 3.

Check end gap with feeler gauge the oil ring groove into the next ring groove. 5 HP Outboard. Troubleshooting & Repair Manual Section 4. Overhaul Inspect Crankshaft Figure 70 — Crankpin Dimensions CAUTION: Always replace a bent crankshaft. Shows wear points to be checked on Figure 72 crankshaft. Discard crankshaft if worn smaller than the following minimum diameter specifications. 5 HP Outboard.

Troubleshooting & Repair Manual Section 4. Overhaul Inspect Camshaft Figure 74 — Cylinder Measurements 1. Inspect gear teeth. Replace the (Figure 73) camshaft if the teeth are worn or nicked. Figure 73 — Camshaft.

5 HP Outboard. Troubleshooting & Repair Manual Section 4. Overhaul Hone Cylinder Do not extend hone more than 3/4 - 1' (19mm - 25mm) at 1. Place hone in middle of cylinder bore.

Tighten either end of cylinder bore adjusting knob with finger or small screwdriver until 6. 5 HP Outboard. Troubleshooting & Repair Manual Section 4. Overhaul Cylinder Cleaning Check Crankshaft Bearings It is most important that the entire cylinder and crankcase Check the crankshaft bearings in the cylinder and sump be thoroughly cleaned after honing. 5 HP Outboard. Troubleshooting & Repair Manual Section 4.

Overhaul 3. Stake bearing to cylinder as shown (Figure 81).

Figure 79 — Remove DU ™ Magneto Bearing Figure 81 — Stake Cylinder Bearing Oil Seals Install DU™ Magneto Bearing Install new oil seals whenever engine is disassembled. 5 HP Outboard. Troubleshooting & Repair Manual Section 4.

Overhaul. 5 HP Outboard. Troubleshooting & Repair Manual Section 5.

Assembly Assembly Install Welch Plug Piston and Connecting Rod Install Choke Shaft Piston Rings Install Throttle Shaft Compress Piston Rings Install Inlet Needle and Float Crankshaft Installation Install Carburetor Install Connecting Rod &. 5 HP Outboard. Troubleshooting & Repair Manual Section 5. Assembly. 5 HP Outboard. Troubleshooting & Repair Manual Section 5.

Assembly ASSEMBLY Piston and Connecting Rod 2. Install the center and top rings with the ID mark facing the top of the piston. The piston pin is a slip fit in both the piston and connecting rod. 5 HP Outboard. Troubleshooting & Repair Manual Section 5. Assembly Crankshaft Installation NOTE: The notch in the connecting rod cap must engage the tab on the (Figure 87) 1.

Thermodynamics statistical thermodyn…. The authors have also added new sections on chemical and phaseequilibrium, and expanded their discussions of correlations and scattering, quantizedfields, finite-size effects, and the fluctuation-dissipation theorem.

Select a seal protector based on size of crankshaft mag journal. 5 HP Outboard. Troubleshooting & Repair Manual Section 5. Assembly 7.

Use Torque Wrench (#19393) to torque connecting Figure 90 — Torque Sump Cover rod cap screws to 100 in. Rotate crankshaft two revolutions to make sure crankpin and rod are not binding during rotation. 5 HP Outboard. Troubleshooting & Repair Manual Section 5. Assembly 3.

Install coil mounting screws finger tight. Figure 92 — Shimming The Crankcase Cover Armature Air Gap 1. Pull left side of armature away from flywheel and tighten left screw. 5 HP Outboard. Troubleshooting & Repair Manual Section 5.

Assembly Figure 96 — Valve Stem Seals Cylinder Head Assembly Install Cylinder Head Plate and Rocker Arm Studs 1. Place new cylinder head plate gasket and cylinder head plate on cylinder head. 5 HP Outboard.

Troubleshooting & Repair Manual Section 5. Assembly Install Rocker Arms 3. Compress spring until valve stem extends through large end of retainer slot.

Continue to press until 1. Install push rods through push rod (Figure 99) small end of slot can slide into groove on valve stem. 5 HP Outboard. Troubleshooting & Repair Manual Section 5.

Assembly Adjust Valve Clearance Figure 102 — Adjusting Valve Clearance Check valve clearance while engine is cold. Turn crankshaft until piston is at TDC of the compression stroke. 5 HP Outboard. Troubleshooting & Repair Manual Section 5.

Assembly 2. Press in until plug is flat. Do not cave in plug. Install Inlet Needle and Float 3. After plug is installed, seal outside edge of plug with 1. 5 HP Outboard.

Troubleshooting & Repair Manual Section 5. Assembly Install Carburetor Install Pulley and Spring 1. Lay starter housing on workbench. Place a new intake gasket between (Figure 107) the control bracket and the cylinder head. 5 HP Outboard. Troubleshooting & Repair Manual Section 5.

Assembly Install Pawls, Pawl Springs & 4. While holding retainer, rotate pulley to extend and retract pawls. If the pawls do not extend and retract, Retainer Assembly remove retainer and reinstall. 5 HP Outboard. Troubleshooting & Repair Manual Section 5. Assembly Gear Case Assembly 5. Pull rope until knot rests against pulley 1.

Install the shift cam/rod to the gear Figure 114 — Securing Rope (Figure 116) case 2. Install the shift shaft support. 5 HP Outboard. Troubleshooting & Repair Manual Section 5. Assembly 4. Install the forward gear and bearing assembly 8. Apply Anti-Seize to the carrier threads.

To the housing 9. Install the carrier assembly to the gear case and align. 5 HP Outboard. Troubleshooting & Repair Manual Section 5. Assembly IMPORTANT 15.

Install the gear case assembly to the midsection.: The locating ridges of the clamp must engage the slot in the rod. Torque the screw to 60 in. 5 HP Outboard. Troubleshooting & Repair Manual Section 5. Assembly NOTE: Always torque the carrier with the gear 2.

8 Hp Briggs And Stratton Engine Manual

Insert brake shoe to port side tilt (Figure 126) case attached to the midsection (Figure 124) bracket 3. Locate reverse hook to port side tilt bracket with Figure 124 —. 5 HP Outboard. Troubleshooting & Repair Manual Section 5.

Assembly Install Power Head Figure 127 — Transom Bracket 1. Grease the shift lever pockets under the neutral switch and the shift lever retaining (Figure 129) plate. Grease the hex end of drive shaft spring as shown. 5 HP Outboard. Troubleshooting & Repair Manual Section 5.

Assembly 4. Secure the power head to the midsection with two 3. Knot the end of the rope with a figure 8 knot bolts on the port side and one bolt on the starboard. 5 HP Outboard.

Troubleshooting & Repair Manual Section 5. Assembly 3. Press on the throttle to ensure that it is seated firmly 7. Install the limiting cap to the idle (Figure 134) against the idle adjusting screw. Mixture screw 4.

5 HP Outboard. Troubleshooting & Repair Manual Section 5. Assembly. 5 HP Outboard.

Troubleshooting & Repair Manual Section 6. Appendix Appendix Outboard Engine Fastener Specifications Lower Unit Fastener Specifications Appendix Ignition System Wiring Diagram Component Location - Gear Case Component Location-Midsection. 5 HP Outboard.

Troubleshooting & Repair Manual Section 6. Appendix APPENDIX Outboard Engine Fastener Specifications Blower Housing 3/8' 85 in. (10 Nm) Carburetor 3/8' 80 in. (9 Nm) Connecting Rod 5/16' 100 in. (11 Nm) Cylinder Head Bolt 3/8'. 5 HP Outboard. Troubleshooting & Repair Manual Section 6.

Appendix Propeller Nut 90 in. (10 Nm). Reed-Switch Screw. (4 Nm) Safety/Engine Stop Switch 20 in. (2 Nm) Shift Lever Screws 35 in. (4 Nm) Shift Rod Clamp Screw 35 in. 5 HP Outboard.

Troubleshooting & Repair Manual Section 6. Appendix Component Location — Gear Case.

5 HP Outboard. Troubleshooting & Repair Manual Section 6. Appendix Component Location - Gear Case 1.

Propeller Shaft Carrier (LH Thread) 3. Reverse Gear 5. Propeller Shaft 6. Sliding Clutch 8. 5 HP Outboard. Troubleshooting & Repair Manual Section 6. Appendix Component Location — Midsection.

5 HP Outboard. Troubleshooting & Repair Manual Section 6. Appendix Component Location-Midsection 1. Shift Lever 2. Shift Lever Handle 3. Screw (5 used) 5. Upper Shift Rod 6.

Tilt Bracket (LH - Port) 8. Brake Shoe 9. 5 HP Outboard. Troubleshooting & Repair Manual Section 6.

Appendix.

. Model Numbers on Murray riding lawn mowers are found on the back of the mower or under the seat. Model numbers on Murray push mowers and walk behind mowers are normally on the center of the deck between the brackets that mount the lower handle. If your manual is still not found after verifying the model number, please see our for more information. Please note that support for models built in 2005 or prior is not available.

If you are looking to purchase Murray parts, please see our for more information.